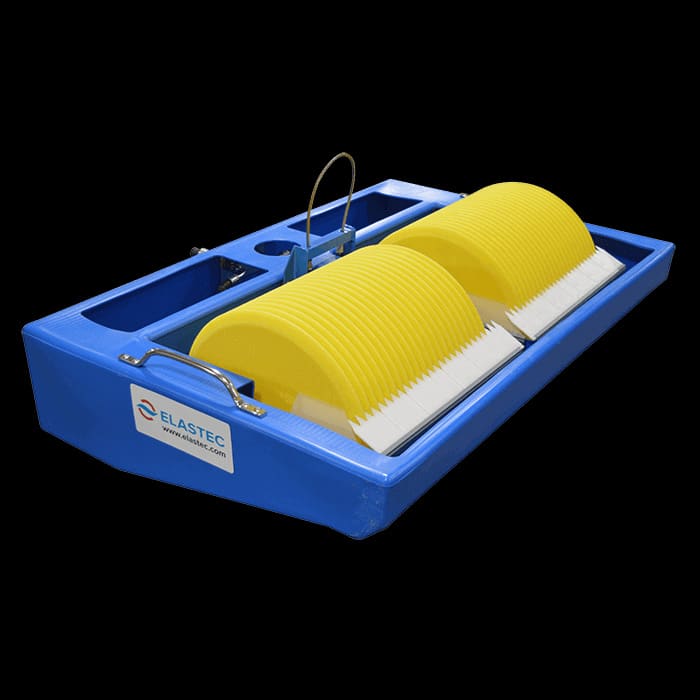

CRX Oil Skimmers For Acidic Environments

Elastec Drum skimmers are well known and respected in oil spill and processing environments. The CRX models have been customized for the copper mining industry, recovering valuable organic oils from acidic raffenate ponds.

Three models are now available, the MiniMax CRX, MiniMax CRXX and the 118 CRX. The CRXX is the latest model with 316 stainless steel components for even more corrosion resistance. The latter model has grooved in the surface of the rotating drums, enhancing the recovery rate.

Solvent extraction and electrowinning (SX/EW) is a two-stage hydrometallurgical process that first extracts and upgrades copper ions from low-grade leach solutions into a solvent containing a chemical that selectively reacts with and binds the copper in the solvent. The copper is extracted from the solvent with strong aqueous acid which then deposits pure copper onto cathodes using an electrolytic procedure (electrowinning).

SX/EW processing is best known for its use by the copper industry, where it accounts for 20% of worldwide production, but the technology is also successfully applied to a wide range of other metals including cobalt, nickel, zinc, and uranium.

Specifications

| Specification | MiniMax CRX | MiniMax CRXX | 118 CRX |

|---|---|---|---|

| Frame | Polyethylene HD | Polyethylene HD | Polyethylene HD |

| Drum Style | Smooth | Smooth | Grooved |

| Drums | Polyethylene HD | Polyethylene HD | Polyethylene HD |

| Drum Shafts | SS 304 | SS 316 | SS 304 |

| Gearbox | Powder Coated | Powder Coated | Powder Coated |

| Bearings | SS 440C / PBT | SS 440C / PBT | SS 440C / PBT |

| U Joint | SS 304 | SS 316 | SS 304 |

| Wiper Retainer | SS 304 | SS 316 | SS 304 |

| Discharge Coupling | Poly | Poly | Poly |

| Drive | Pneumatic | Pneumatic | Pneumatic |

| Max Temperature | 130º F / 54º C | 130º F / 54º C | 130º F / 54º C |

The CRX models have been successfully employed in Copper mines. We also supply floating oil containment booms that can concentrate product around the skimmer, improving recovery rates. These booms are manufactured in PVC, without metal fasteners.