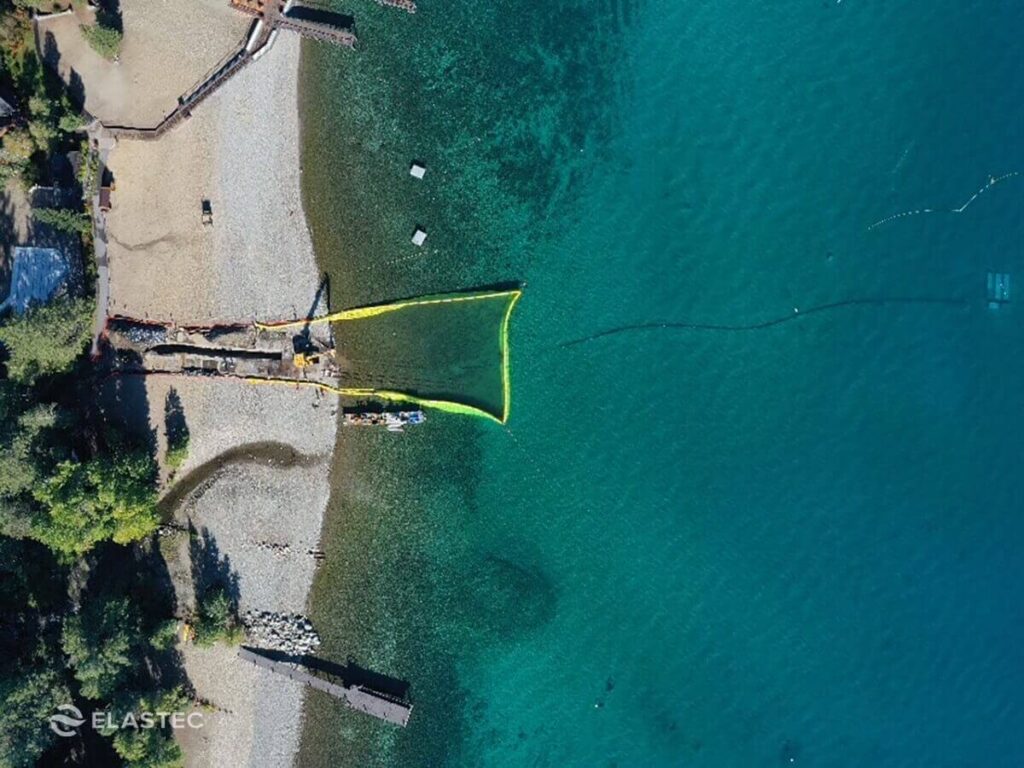

If you’re managing in-water construction, shoreline stabilization, dredging, or bridge repair, you’ve likely worked with floating silt curtains (also called turbidity curtains or sediment curtains). They’re essential for staying compliant with environmental regulations and keeping suspended sediments from spreading into surrounding water bodies.

One of the most common deployment mistakes? Going too deep.

Let’s set the record straight: Your silt curtain should NOT touch the bottom.

Here’s what you, as a contractor, need to know to deploy silt curtains correctly, avoid damage, and keep your project running smoothly and in compliance.

Why Deeper Isn’t Better

1. Silt and Turbidity Curtains Aren’t Designed to Block Flow

Silt curtains aren’t dams. They’re designed to slow water movement, not stop it. The goal is to give suspended sediment time to settle, not to block it outright. The fabric is permeable or semi-permeable, and it won’t hold back moving water — and that’s by design.

Trying to use a curtain to block flow only increases pressure on the system and shortens its life.

2. Dragging the Bottom Tears the Curtain

If the curtain reaches the bottom, it will snag on rocks, stumps, or debris — especially in uneven or rocky conditions. Many contractors try to keep the curtain down with sandbags or added weights, but this causes more problems:

- Tears or punctures in the curtain

- Reduced functionality

- Costly repairs or full replacement

Keep it off the bottom. Your budget will thank you.

3. Sediment Can Settle on the Curtain

In calmer water, suspended sediment can accumulate right on top of the curtain if it’s sitting too low. This creates two major issues:

- It makes the curtain extremely difficult to retrieve once the project is done.

- The buildup can weigh the curtain down, causing it to sag, tear, or become ineffective.

You want that sediment settling on the bottom of the waterbody, not your equipment.

Best Practices: Setting the Right Depth

Here’s a simple deployment checklist to help you get it right the first time:

1. Measure Depth Accurately

Take depth readings across your work area. Account for tides, currents, and seasonal water level changes.

2. Leave Clearance from the Bottom

Keep 1–2 feet of clearance between the bottom of the curtain and the waterbed. This allows water to flow underneath, keeps the curtain from dragging, and maintains its integrity.

3. Match Curtain Type to Conditions

Choose the right type of curtain for your project:

- Type 1: Calm, inland waters — lakes, ponds, small canals

- Type 2: Moderate flow — rivers, bays, larger lakes

- Type 3: High flow or tidal — coastal, open water, or barge activity

4. Deploy Parallel to the Flow

For better performance and less wear and tear, always install the curtain parallel to the flow of water — not across it.

Pro Tips for Contractors

- Anchoring is important. Use anchors, tension lines, and mooring buoys to stabilize the curtain without forcing it down.

- Avoid over-sizing. Ordering longer-than-needed curtains leads to drag, excess wear, and harder retrieval.

- Monitor and adjust. After storms or heavy activity, inspect the curtain and make sure it hasn’t shifted or become buried.

Final Word

If you’re asking, “How deep should my silt curtain be?”, the right move is to stay off the bottom. A curtain that floats just above the waterbed, runs parallel to the current, and avoids added weight will perform better, last longer, and keep you in compliance with EPA or local environmental regulations.

Bottom line: Don’t force your curtain to do a job it wasn’t built for. Deploy it smart — and let it work the way it’s supposed to. Elastec’s team of experts can help you make the right decisions for your project. Contact us today.

Connect With Us

Sign up for our newsletters to receive the latest news and product information from Elastec.