RUBBERMAX

RubberMax inflatable oil containment boom is produced with the latest materials and techniques. The materials have been extensively tested according to ASTM and military standards including puncture and abrasion resistance as well as tear and tensile strength. The construction has two plies of polyester reinforcing fabric coated in synthetic rubber with compounds which are resistant to the elements and oil. American Marine, a division of Elastec, has been manufacturing quality floating boom and barrier products since 1967. For storage, we offer a line of boom reels. Learn about how Elastec’s oil booms meet ASTM and ISO standards, and OPA90 regulations. Fill out our questionnaire and tell us about your project.

RubberMax is designed with a high buoyancy to weight ratio, providing the boom with excellent wave riding and oil retention characteristics. It lies flat when stowed, optimizing storage space.

The chain acts as a tension member for added strength and resistance of towing forces. The boom is supplied with ASTM compliant interchangeable end connectors for rapid coupling of sections. This boom has been supplied around the world including the US Navy.

RubberMax is a heavy-duty boom with excellent resistance to sunlight, puncture, abrasion and tearing. As standard, the RubberMax range of booms are supplied in manageable section lengths (98 & 164ft / 30 and 50m). These shorter sections allow for a greater flexibility of deployment configurations.

The RubberMax boom has individually filled air chambers, each chamber being equipped with the patented Monsun XG valve. This valve has a built-in non-return with a rubber protection collar – protecting it from damage during deployment and storage on the boom reel. Our high capacity air blowers rapidly fill the individual air chambers as the boom is deployed into the water.

Contact us to learn more.

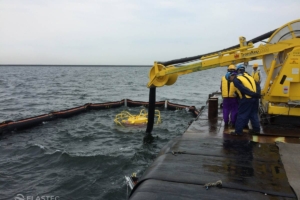

RUBBERMAX PHOTOS

RUBBERMAX SPECIFICATIONS

| Model | 2000 | 1800 | 1500 | 1300 | 1000 |

| Connector Height | 78 in / 2000 mm | 71 in / 1800 mm | 59 in / 1500 mm | 51 in / 1300 mm | 39 in / 1000 mm |

| Operation Height | 67 in / 1700 mm | 59 in / 1500 mm | 47 in / 1200 mm | 43 in / 1100 mm | 31 in / 790 mm |

| Freeboard | 24 in / 600 mm | 24 in / 600 mm | 20 in / 500 mm | 17 in / 440 mm | 14 in / 360 mm |

| Draft | 43 in / 1100 mm | 35 in / 900 mm | 28 in / 700 mm | 26 in / 660 mm | 17 in / 430 mm |

| Air Chamber Length | 177 inch / 4.5 m Seamless Individual Air Chambers | 177 inch / 4.5 m Seamless Individual Air Chambers | 177 inch / 4.5 m Seamless Individual Air Chambers | 177 inch / 4.5 m Seamless Individual Air Chambers | 177 inch / 4.5 m Seamless Individual Air Chambers |

| Section Length | 82, 98 or 164 ft / 25, 30 or 50 m* | 82, 98 or 164 ft / 25, 30 or 50 m* | 82, 98 or 164 ft / 25, 30 or 50 m* | 82, 98 or 164 ft / 25, 30 or 50 m* | 82, 98 or 164 ft / 25, 30 or 50 m* |

| Bottom Tensions | Galvanized Steel Chain | Galvanized Steel Chain | Galvanized Steel Chain | Galvanized Steel Chain | Galvanized Steel Chain |

| Weight | 10 lb/ft - 15 kg/m | 9 lb/ft - 13.5 kg/m | 8 lb/ft - 12 kg/m | 6 lb/ft - 9 kg/m | 4.4 lb/ft - 6.5 kg/m |

*Custom section lengths and sizes available

Containment Boom Reels

Oil containment boom reels are the fastest and most efficient means for storage, deployment and recovery of longer lengths of boom. Most of our reels have the ability to free-wheel to speed up deployment. Our boom reels may be hydraulic or manually operated and are suitable for both inflatable boom and some models of foam flotation boom.

OPA90 Regulations and ASTM Standards for Elastec Oil Booms

Elastec oil booms are manufactured in accordance with OPA90 regulations and ASTM standards, such as;

- F625/F625M-94(2022) Standard Practice for Classifying Water Bodies for Spill Control Systems

- F715-07(2023) Standard Test Methods for Coated Fabrics Used for Oil Spill Control and Storage

- F818-16(2020) Standard Terminology Relating to Spill Response Booms and Barriers

- F962-04(2023) Standard Specification for Oil Spill Response Boom Connection: Z-Connector

- F1093-99(2023) Standard Test Methods for Tensile Strength Characteristics of Oil Spill Response Boom

- F1523-94(2023) Standard Guide for Selection of Booms in Accordance With Water Body Classifications

- F1599-95(2024) Standard Guide for Collecting Performance Data on Temporary Storage Devices

- F1657/F1657M-96(2024) Standard Practice for Emergency Joining of Booms with Incompatible Connectors

- F2084/F2084M-01(2024) Standard Guide for Collecting Containment Boom Performance Data in Controlled Environments

- F2438-04(2022) Standard Specification for Oil Spill Response Boom Connection: Slide Connector

- F2682-07(2024) Standard Guide for Determining the Buoyancy to Weight Ratio of Oil Spill Containment Boom

- F2683-11(2024) Standard Guide for Selection of Booms for Oil-Spill Response

- F3694-24 Standard Guide for Towing and Anchoring Oil Booms

Elastec oil containment booms conform with ISO standard 17325-1 (2014) Ships and marine technology, Marine environment protection, Oil booms – Part 1: Design requirements & Part 3: End Connectors.

Containment Boom Questionnaire

Thank you for considering the Elastec Containment Boom for your project. Please complete a few simple questions that will help define your requirement.