FLEXIBELT BARRIER

FlexiBelt is a unique spring-loaded floating containment barrier designed to be used by ships during refueling and product transfer operations. It will ride up and down against the ships’ hull and seawall, automatically adjusting to the changing distances and waterline. Typically, two FlexiBelts are deployed with one upstream and one downstream (facing in opposite directions). American Marine, a division of Elastec, has been manufacturing quality floating barrier products since 1967. Learn about how Elastec’s oil booms meet ASTM and ISO standards, and OPA90 regulations.

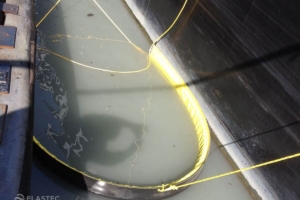

Fitted with full-length fiberglass battens for flexibility, a pair of FlexiBelts seal the area of potential spills. Simply tie a line to each of the outer ends of the containment barier and another to the grommet in the middle. Fold the unit in two and drop it down between the ship and the sea wall (or two ships). The FlexiBelt will spring open and seal itself against the two. As the distance between the two changes, the belt will compress or open by itself.

Alternatively, the FlexiBelt is a very simple way of segmenting walled ponds and oily water separators without any fabrication or installation. Select a Flexibelt that’s approx 30% wider than the distance between walls.

FlexiBelt is available in multiple sizes ranging from 6 – 20 ft / 1.8 – 6 m.

Contact us to discuss your project specifications.

FLEXIBELT PHOTOS

FLEXIBELT VIDEO

OPA90 Regulations and ASTM Standards for Elastec Oil Booms

Elastec oil booms are manufactured in accordance with OPA90 regulations and ASTM standards, such as;

- F625/F625M-94(2022) Standard Practice for Classifying Water Bodies for Spill Control Systems

- F715-07(2023) Standard Test Methods for Coated Fabrics Used for Oil Spill Control and Storage

- F818-16(2020) Standard Terminology Relating to Spill Response Booms and Barriers

- F962-04(2023) Standard Specification for Oil Spill Response Boom Connection: Z-Connector

- F1093-99(2023) Standard Test Methods for Tensile Strength Characteristics of Oil Spill Response Boom

- F1523-94(2023) Standard Guide for Selection of Booms in Accordance With Water Body Classifications

- F1599-95(2024) Standard Guide for Collecting Performance Data on Temporary Storage Devices

- F1657/F1657M-96(2024) Standard Practice for Emergency Joining of Booms with Incompatible Connectors

- F2084/F2084M-01(2024) Standard Guide for Collecting Containment Boom Performance Data in Controlled Environments

- F2438-04(2022) Standard Specification for Oil Spill Response Boom Connection: Slide Connector

- F2682-07(2024) Standard Guide for Determining the Buoyancy to Weight Ratio of Oil Spill Containment Boom

- F2683-11(2024) Standard Guide for Selection of Booms for Oil-Spill Response

- F3694-24 Standard Guide for Towing and Anchoring Oil Booms

Elastec oil containment booms conform with ISO standard 17325-1 (2014) Ships and marine technology, Marine environment protection, Oil booms – Part 1: Design requirements & Part 3: End Connectors.